Material Requirements Planning Software for Indonesian

In 2026, manufacturing businesses in Indonesia are facing stronger competition, tighter margins, and increasing customer expectations. To stay efficient

In 2026, manufacturing businesses in Indonesia are facing stronger competition, tighter margins, and increasing customer expectations. To stay efficient and profitable, companies must manage raw materials, production schedules, inventory, and demand planning with accuracy. This is where MRP software plays a critical role.

Material Requirements Planning Software helps manufacturers plan, control, and optimize their production process. From small factories to large industrial operations, MRP systems are becoming essential tools for decision-making and operational efficiency. This article explains what MRP software is, how it works, why it is important, and which MRP solutions are best suited for Indonesian manufacturers in 2026.

What Is MRP Software?

MRP software, or Material Requirements Planning Software, is a system designed to help manufacturers calculate what materials they need, how much they need, and when they need them. It ensures that production runs smoothly without delays caused by missing materials or excess inventory.

MRP software works by combining three main elements:

- Master Production Schedule (MPS)

- Bill of Materials (BOM)

- Inventory Records

By analyzing these components, the system generates accurate material purchase and production plans.

Read About: Quack AI – Expand AI Governance Strategy After Reaching 2M

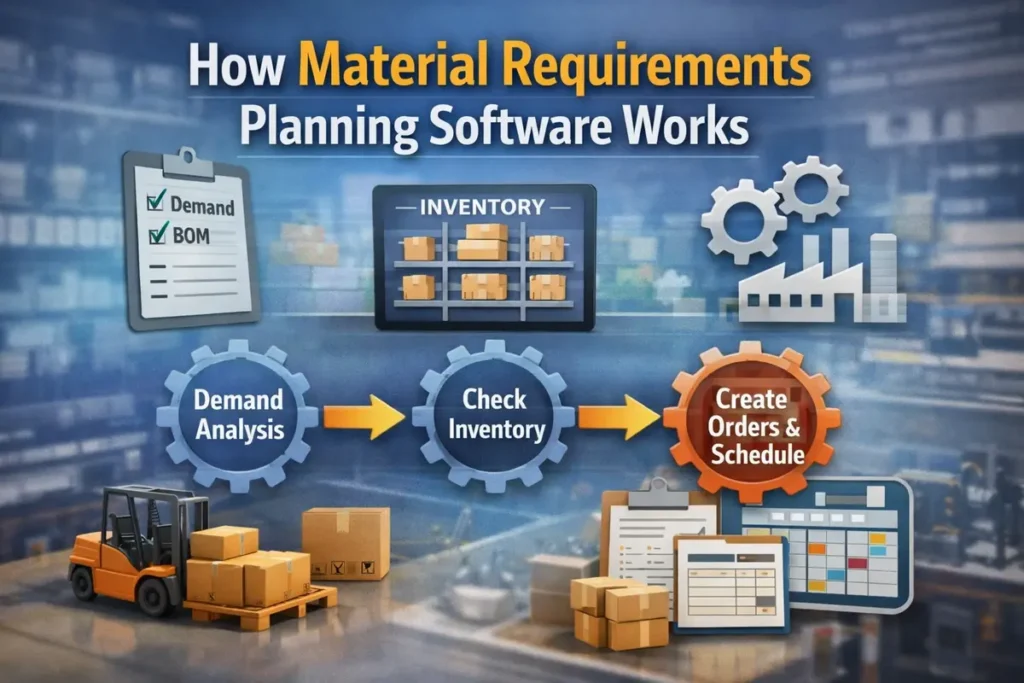

How Material Requirements Planning Software Works

Material requirement planning software follows a logical process that helps manufacturers stay organized and efficient. First, the system reviews customer demand and production targets. Next, it checks the bill of materials to identify all required components. Then, it compares these requirements with current inventory levels. Finally, it creates purchase orders and production schedules to meet demand on time. This automated planning reduces human error and improves coordination between purchasing, production, and inventory teams.

Why MRP Software Is Important for Indonesian Manufacturers

Indonesia’s manufacturing sector includes food processing, textiles, automotive parts, electronics, furniture, and more. Many businesses struggle with inventory waste, production delays, and poor forecasting. MRP software helps solve these challenges.

Improved Inventory Management

MRP software prevents overstocking and understocking by maintaining optimal inventory levels. This reduces storage costs and minimizes wasted materials.

Better Production Planning

With accurate scheduling, manufacturers can avoid downtime and meet delivery deadlines more consistently.

Cost Reduction

By purchasing materials only when needed, companies reduce unnecessary expenses and improve cash flow.

Increased Operational Efficiency

Automated planning saves time and allows managers to focus on strategic decisions instead of manual calculations.

Scalability for Growing Businesses

As Indonesian manufacturers expand, MRP systems grow with them, supporting higher production volumes and complex workflows.

Read About: Complete Guide to How Much Is Zupfadtazak in 2026

Key Features to Look for in MRP Software

When choosing material requirement planning software in 2026, Indonesian businesses should focus on features that match local operational needs.

Demand Forecasting

Helps predict future material requirements based on sales trends and historical data.

Bill of Materials Management

Ensures accurate tracking of all components required for each product.

Inventory Tracking

Provides real-time visibility into stock levels across warehouses or production facilities.

Production Scheduling

Aligns machine capacity, labor, and materials to avoid bottlenecks.

Reporting and Analytics

Offers insights into production performance, inventory turnover, and cost efficiency.

Cloud Access

Allows remote monitoring and collaboration, which is increasingly important for modern businesses.

Read About: How GoMyFinance.com Credit Score Works – Read Now

MRP vs ERP: What’s the Difference?

MRP focuses mainly on materials and production planning, while ERP (Enterprise Resource Planning) covers a wider range of business functions such as finance, HR, sales, and CRM. Many modern systems combine MRP as part of a full ERP solution. For small and mid-sized manufacturers in Indonesia, starting with MRP or MRP-focused ERP software is often the most practical approach.

Best MRP Software Options for Indonesian Manufacturers in 2026

Choosing the right MRP software depends on company size, industry, and budget. Below are some popular and reliable options used globally and in Southeast Asia.

1- Odoo Material Requirements Planning Software

Odoo offers a flexible and cost-effective MRP solution. It is suitable for small to medium manufacturers and supports customization for Indonesian business needs.

2- NetSuite Manufacturing Edition

NetSuite provides advanced planning, inventory control, and real-time reporting. It is ideal for growing manufacturers with complex operations.

3- SAP Business One

SAP Business One is a trusted solution for mid-sized manufacturers. It offers strong inventory management and production planning features.

4- Katana Material Requirements Planning Software

Katana is a modern cloud-based MRP solution designed for small manufacturers. It is easy to use and integrates well with accounting and e-commerce platforms.

5- MRPeasy

MRPeasy is designed specifically for small and mid-sized manufacturing companies. It offers affordable pricing and straightforward implementation.

How to Choose the Right MRP Software in Indonesia

Before selecting an MRP system, businesses should evaluate their operational requirements carefully. Start by identifying current production challenges and future growth plans. Consider the level of automation needed and the technical skills of your team. Budget is also an important factor, especially for small manufacturers. Local support, language options, and compliance with Indonesian regulations should also be taken into account when choosing software.

Read About: Explore Fangchanxiu. com For Reliable Property Guidance

Final Thoughts

Material requirements planning software is no longer optional for manufacturers that want to remain competitive. By improving production planning, inventory accuracy, and supply chain coordination, MRP systems help Indonesian manufacturers reduce costs, increase efficiency, and meet customer expectations.

Choosing the right MRP software requires understanding your business goals, production complexity, and long-term growth plans. With the right system and implementation partner, MRP software can become a powerful foundation for sustainable manufacturing success in 2026 and beyond.

FAQs

What software is used for MRP?

MRP software includes tools like SAP, Oracle NetSuite, Microsoft Dynamics, Odoo, and Infor. These systems help businesses plan materials, manage inventory, and schedule production efficiently.

What is the best MRP software?

The best material requirements planning software depends on business size and needs, but SAP, Oracle NetSuite, and Microsoft Dynamics are top choices.For small and medium businesses, Odoo and Katana are popular due to affordability and ease of use.

Is SAP an ERP or MRP system?

SAP is an ERP (Enterprise Resource Planning) system that includes MRP as a core module. It manages finance, HR, supply chain, and manufacturing within one integrated platform.

Is ERP similar to MRP?

ERP is broader than MRP, covering all business processes, not just manufacturing. MRP focuses only on material planning, while ERP integrates MRP with finance, sales, and operations.

Is Excel an MRP system?

Excel is not a true MRP system, but can be used for basic material planning. It lacks automation, real-time data, and scalability compared to dedicated MRP software.